….can produce high quality lint at rates up to 15 bales per hour.

- Exclusive ginning design. Patent #4313242

- A forward-tilting ginning breast allows convenient inspection of the huller ribs, ginning ribs and roll box.

- Open-end huller ribs permit high-capacity feeding of the seed roll.

- Placement of the picker roller eliminates force feeding the gin saws.

- Huller front tilts forward for accessibility to the picker rollers and the roll box. The seed roll can be easily dumped.

- Compact overall design, featuring rigid-weld steel construction.

- Optional open-end huller ribs.

The BAJAJ CONEAGLE Golden Eagle

The BAJAJ CONEAGLE Golden EagleSeries 161 Saw Gin

…can produce high quality lint at rates

up to 15 bales per hour.

16″ Gin Saws – Featuring scientifically designed saw teeth, tempered for super-strength. The design creates less friction at the ginning point. Saws are of standard gauge and are precision ground.

Flow of Cotton

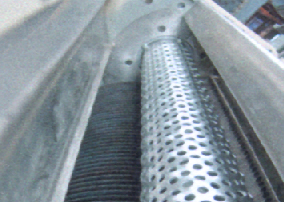

Lint is pulled and separated from the cotton seed by the gin saw rotating between ginning ribs. The saw teeth carry the lint through the evenly spaced ginning ribs at the ginning point and the seed is left behind in the roll box. The saw consists of 161 saw blades mounted on a journal that rotates at 615 RPM.

The saw blades have 330 – teeth and are 16 inches in diameter. Approximately 50 percent of the seed passes through holes in the patented seed tube located in the center of the roll box where they are conveyed to the ends of the gin and discharged to the seed conveyor below the gin. The remaining seed is purged from the bottom of the seed roll and falls into the seed conveyor. Lint is removed from the saw by the doffing brush.

Overhead Moting – Jet lint cleaner efficiency. Positive wiper action. No trash return. Moting can be regulated as cotton conditions dictate.

Positive Brush Doffing – Lint is removed directly from the gin saws at super-capacities producing a smooth sample. Features positive lint discharge and adjustable air intake.

Lower Moting – Adjustable mote board allows for additional cleaning.

Capacity :

15 bales per hour

Saw :

16″ dia, 161 saw blades, 615 rpm

Doffing Brush :

15″ dia, 20 rows of brushes, 1552 rpm

Seed Roll Tube :

5 inch steel tube rotates at 270 rpm, 4 inch conveyor rotates at 854rpm

Gin Motor :

(Not included with machine) 150hp,1800 rpm, 60Hz

Dimensions

Length (front, with covers):

(3873mm) 152-1/2 in.

Height (from the bottom

of feeder) :

(1343mm) 52-7/8 in.

Width (with covers) :

(2330mm) 91-3/4 in.

Saw Shaft centerline to floor :

(730mm) 28-3/4 in.

Weight (approximate)

(3175kg) 7000 lb.

All Capacities are subject to cotton varieties, conditions and personnel All designs, specifications and ratings are subject to change without notice.