USP of BAJAJ-CEC 201 EagleMax Gin Stand

The Continental Golden 201 EagleMax Gin Stand are representatives of the most important changes in gin design in the past 50 years.

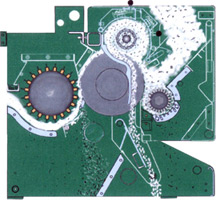

The most notable of these design innovation is the Seed Conveyor Tube. This patented device is located in the seed roll allowing as much as 50% of the seed to be removed from the middle of the seed roll rather than through the bottom. The remaning 50% of the seed pass to the bottom of the gin. In all other gins, 100% of the seed is required to pass through to the bottom of the Gin.

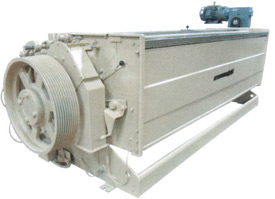

The BAJAJ-CEC 201 EagleMax Gin Stand

…. can produce high quality lint at proven rates of 25 bales per hour.

BAJAJ-CEC designed ginning system equipped with the exclusive high capacity Seed Roll Conveyor Tube.

A forward-tilting ginning breast allows convenient inspection of the ginning ribs, roll box and optional huller ribs.

Placement of the new designed picker roller eliminates force-feeding the gin saws.

Huller front tilts forward for accessibility to the picker roller and the roll box. The seed roll can be easily dumped.

BAJAJ-CEC 201 gin frame is equipped with a rib rail for the addition of huller ribs if cotton conditions or customer warrants their use.

Compact overall gin design, featuring rigid-weld steel construction.

Segmented heads for easy front removal of gin saw and gin brush.

Optional open-end huller ribs.

Seed Roll Conveyor Tube· (removes ginned seed from the center of the seed roll) This exclusive 5″ (127mm) diameter louvered design rapidly removes seed. Speed of rotation is coordinated with the natural rotation of the seed roll for effective, positive results. Sealed bearings throughout.

Top Mounted Ginning Ribs with Inserts-Engineered for safety and high performance, featuring super-strength at the ginning point. Cantilever rib design for tag relief.

16″ Gin Saws – Featuring scientifically designed and heat tempered saw teeth The design creates less friction at the ginning point. Saws are of standard gauge and are preision ground, mounted on a 6 7/8″ {174.6 mm} diameter Saw Mandrel with 4 7/16· (112.7 mm) Pillow Block Bearings.

Brush & Saw Removal – Segmented heads for easy front removal of gin saw and gin brush.

Flow Of Cotton

Lint is pulled and separated from the cotton seed by the gin saw rotating between ginning ribs. The saw teeth carry the lint through the evenly spaced ginning ribs at the ginning point and the seed is left behind in the roll box. The saw consists of 201 saw blades mounted on a journal that rotates at 615 RPM. The saw blades have 330-teeth and are 16 inches (406mm) in diameter. Approximately 50 ercent of the seed passes through holes in the seed tube located in the center of the roll box where they are conveyed to the ends of the gin and discharged to the seed conveyor below the gin. The remaining seed is purged from the bottom of the seed roll and falls into the seed conveyor. Lint is removed from the saw by the doffing brush.

Positive Brush Doffing – Lint is removed directly from the gin saws at super-capacities producing a smooth sample. Features positive lint discharge and adjustable air intake.

Lower Moting – Adjustable mote board allows for additional cleaning.

Optional Huller Ribs – Gin Frame supplied with rib rail for optional huller rib Use.

Technical Specifications

Capacity :

201 Saw Gin: 25 Plus bales per hour Gin 15 plus bales per hour

Saw :

16″ (406mm) dia 201 saw blades, 615 rpm

Doffing Brush :

15″ (381mm) dia. 20 rows of brushes, 1550 rpm

Trash Conveyor :

12″ ( 304mm) Drive 93prm

Seed Roll Tube :

Drive 5prm steel tube roller agitator

Gin Motor :

250 hp

Picker Roller :

independent drive 504 rpm

Dimensions

Length (front, with covers):

(4470 mm) 176”

Height (from the bottom

of feeder) :

(1343 mm) 52 7/8”

Width (with covers) :

(2489 mm) 98”

Saw Shaft centerline to floor :

(730 mm) 28 3/4” to floor

Weight (approximate)

(3628 kg) 8000 lb

All Capacities are subject to cotton varieties, conditions and personnel All designs, specifications and ratings are subject to change without notice.