USP of Golden Eagle 24 – D Lint Cleaner

This Lint Cleaner was designed specfically for better cleaning at higher capacities. It operates at capacities exceeding 25 Bales per hour.

The feeding mechanism on the Continantal 24D consists of 3 rollers. The first 2 rollers receive the batt from the doffing rollers and elongate and thin the batt of cotton. The 3rd roller receives the thinned, drawn batt and continues to draw it while compressing the batt against the feed bar for maximum, combing action.

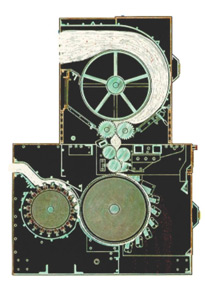

The 24-D Golden Eagle Lint Cleaner is a saw-type, controlled-batt lint cleaner having two main assemblies, the lint cleaner base and the condenser assembly mounted on top of the lint cleaner base. One optional three-phase AC motor powers all drives in the condenser and lint cleaner.

Major components of the condenser assembly consist of a 24-inch diameter perforated screen condenser drum and two grooved doffing rollers. Each end of the condenser drum is connected to an air duct. Air carrying cotton into the drum escapes out the air ducts while the cotton adheres to the drum. Adjustable flapper values on the ducts provide air balance.

Major components of the lint cleaner base assembly consist of three feed rollers, a feed bar, eight cleaning grid bars, a saw cylinder and the doffing brush. Adjustments are provided for maintaining proper position of the components.

Single or Tandem

The Golden Eagle 24-D’s are easily installed in single unit or tandem arrangements behind any gin stand and will more than meet every challenge. Valve configuration allows use of either or both lint cleaners.

Rugged, Trouble-Free Construction

![]() Precision machined feed plate, adjustable for accurate placement, heavily built to hold critical settings

Precision machined feed plate, adjustable for accurate placement, heavily built to hold critical settings

![]() Exclusive concave grid bar design further straightens and aligns fibers for high trash removal with reduced lint loss

Exclusive concave grid bar design further straightens and aligns fibers for high trash removal with reduced lint loss

![]() Exclusive tooth design on wire-wrapped saw insured superior lint retention, easier doffing

Exclusive tooth design on wire-wrapped saw insured superior lint retention, easier doffing

![]() Heavy steel shafts on sealed bearings

Heavy steel shafts on sealed bearings

![]() Easily-removed components

Easily-removed components

Lint enters the condenser and is formed into a batt on the condenser screen. Air carrying the lint passes through the screen on the drum and exits out the two end ducts. The two grooved doffing rollers remove the batt from the condenser and direct it to feed rollers in the lint cleaner. The rear grooved doffing roller is installed with a minimum running clearance from the drum and allows the doffing rollers to form a pressure seat at the discharge point. The front doffing roller is set at 3/8 inch from the condenser drum. As the flow continues, the increased speed of the rollers draw and straighten fibers for the saw.

Rollers draw and direct the batt to the feed rollers and the feed bar which feeds the batt into the saw. The feed roller is under spring tension exerting a force toward the face of the feed bar. The feed roller and feed bar grip the batt so that the fibers are drawn and combed as they are placed on the surface of the saw.

Trash and mote particles thrown to the outside edge of the cotton by centrifugal force are stripped by the cleaning grid bars. The saw carries the cotton to the doffing point where it is removed by the brush. The brush also generates air flow to help convey the lint.

24-D Motor :

40hp, 1750rpm

Brush Cylinder :

17.75 in, cylinder dia, 1655 rpm

Saw Cylinder :

24.0 in, cylinder dia, 908 rpm

Condenser Drum :

24.0 in, cylinder dia, 27.51 rpm with Step Cone Sheave 5.0

Mote Air Requirement

(Per Machine)

4000 cfm

Brush Air Requirement

(Per Machine)

7100 cfm

Dimensions

Length

Inside Heads

(2591mm) 102 in.

Outside of Closed Doors

(3721mm) 146-1/2 in

Outside of Open Doors

(5182mm) 204 in

Width (Outside of Covers)

(1626mm) 64 in

Height (Installed)

Floor to top of Condenser

(2657mm) 104-5/8 in

Floor to top Horizontal Duct

(3442mm) 135-1/2 in

Condenser

(1069kg) 2,400 lbs

Lint Cleaner Base

(3656kg) 8,060 lbs

All Capacities are subject to cotton varieties, conditions and personnel All designs, specifications and ratings are subject to change without notice.