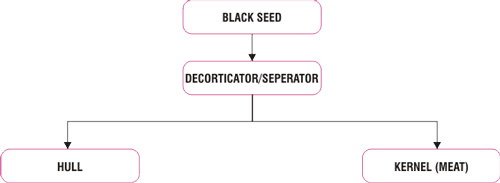

Bajaj-CEC Decorticator / Separator

INTRODUCTION

IMPCO (Later CEC) was the first to envision and implement the modern twin-roll hulling design since 1962. First to incorporate a decorticator with a basket beater and high speed separation. First to successfully process undelinted cottonseed with lowest kernel with hull. Highest Capacity per meter width of twin roll drum.

SALIENT FEATURES

- No uncut seed recycling – virtually 100% of seed is cut and processed

MECHANICAL ADVANTAGES

- Replaceable cutting surface on decorticator roll will process the highest tonnage at the lowest cost.

- Two removable Basket Beater Trays provided for ease of processing multiple oil seeds such as cottonseed

delinted / undelinted, sunflower, soybean and groundnut etc. - Three hull aspiration ducts allows for maximized hull removal and meat purification to obtain desired protein

levels

TECHNICAL SPECIFICATIONS

Capacity – Black Seed

8 to 9 TPH

Twin Roll Motor

25 HP 1500 RPM

Hydraulic Unit Motor

2 HP 1200 RPM

Feeder Motor

1 HP Variable

Cutting Segments

38 (19 per roll)

Shaker Tray Motor

3 HP

Basket Beater Motor

1.5 HP

Air Requirement

5200 CFM

BAJAJ-CEC DECORTICATING OPERATION